Product Guides, Installation Manuals, Specs Sheets & Warranty Information

Brochures & Advocacy Tools

- Smart Crosswalk™ Selection Guide: This guide introduces you to our in-roadway warning light, RRFB, and flashing LED warning sign systems with equipment selection options.

- Lighted Crosswalk Product Matrix: This flyer helps to determine which of our lighted crosswalks is right for your installation location based on number of lanes, posted vehicle speeds, and power source.

- Petition Toolkit — How to Get a Smart Crosswalk: Want a lighted crosswalk in your neighborhood but don’t know where to start? This step-by-step toolkit offers tips on how to gather information and approach your city officials.

- Walkability Checklist:

A checklist for evaluating neighborhood and community walkability and pedestrian safety, including resource tools and funding sources.

Links

- Federal Highway Administration, Pedestrian and Bicycle Safety Team Office Of Safety, Washington, DC

- National Highway Traffic Safety Administration, Traffic Safety Programs Washington, DC

- Pedestrian and Bicycle Information Center (PBIC), UNC Highway Safety Research Center, Chapel Hill, NC

- National Center for Safe Routes to School, Chapel Hill, NC

- State Bicycle & Pedestrian Coordinators

- America Walks

- Alliance for Biking & Walking

- National Complete Streets Coalition

- Partnership for a Walkable America

- Transportation for America

- Local Groups by State

Installation Manuals & Visual Guides

The LightGuard Systems Installation Manual and Visual Guidelines contains complete instructions on adequately installing any of our hardwired products, including:

- in-roadway warning lights

- LED signs

- RRFBs

- solar-powered systems

- any other components related to the installation of a LightGuard Systems lighted crosswalk system or component

Our installation manual is provided in an Adobe PDF download format. For ease of navigation, hyperlinks are provided to all chapters and subsections listed on the index page.

Hardwired Systems IRWL/SIGNS/RRFB

Table of Contents:

- The LightGuard System & Components

- Power System & Components

- In-Roadway Warning Light (IRWL)

- Automatic Activation System - Smart Crosswalk™

- Push-Button Activation

- LED-Enhanced Illuminated Warning Signs

- LightGuard Systems Solar Power Option

- Troubleshooting/Maintenance/After Installation

- Addendum

Wireless Systems SIGNS/RRFB Installation Manual

Installation Manual LGS-WIRELESS UC Systems Jan 2024

Visual Guides

IRWL Installation Tips

LightGuard's in-roadway warning light systems operate on low voltage Direct Current (DC) power and can use either solar power or Alternating Current (AC) power converted to 12v DC.

To ensure system reliability, LightGuard's IRWL crosswalk system is hard-wired. A City Public Works crew or independent installation contractor can install a complete IRWL crosswalk system for a typical 2-lane mid-block crosswalk within 1-3 days.

Installation time varies based on the number of traffic lanes, the chosen IRWL equipment, and the installing crew's skill. Most IRWL systems are retrofitted to existing crosswalks.

The first step is determining the layout pattern or placement of each IRWL module according to the lane lines, parking lane, sidewalk, and crosswalk locations. (See Visual Installation Guidelines above, IRWL layouts, and Zone of Convergence).

Once the layout is determined, the next step is to saw cut for the IRWL system wiring. The saw cut is generally no wider than .5″ wide and no greater than 2″ deep. Either conduit or direct burial wire can be utilized. Once the saw cut has been completed, locations for base plates are identified, and depression holes are bored into the road surface. (For complete in-depth instructions, please see the LightGuard Installation Manual.

The standard 10″ diameter x 1.5″ deep base plate is made of an ultra-high-strength composite material. It is designed to be permanently embedded into the roadway. This allows for any in-roadway warning light (IRWL) signal head that becomes damaged or inoperable to be repaired with an easy-to-install replacement.

For "snow country" use, we offer a Snow Plow Blade Resistant Base Plate. The case-hardened steel base plate has wingtips on either side of the IRWL signal head and a center nose bridge. When a snowplow blade strikes the base plate, the blade is lifted up and over the top of the IRWL signal head. The steel base plate is 14″ in diameter and is no more than 1.5″ deep.

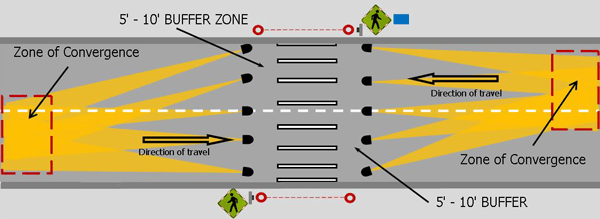

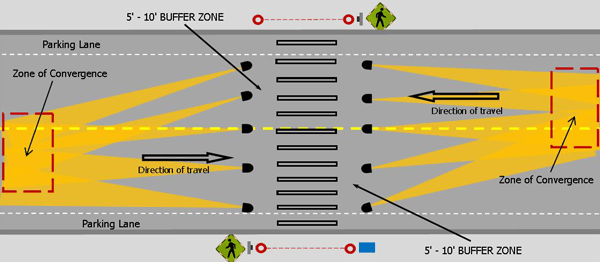

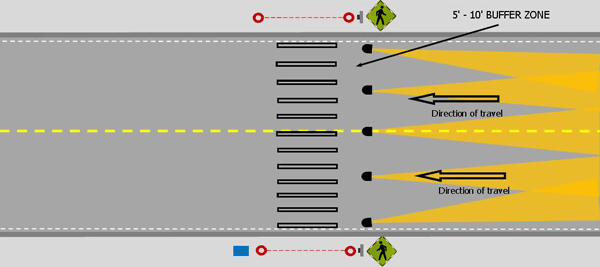

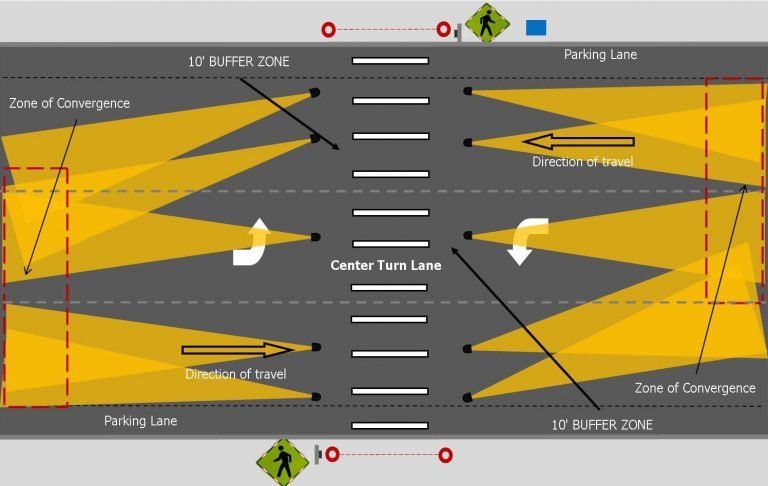

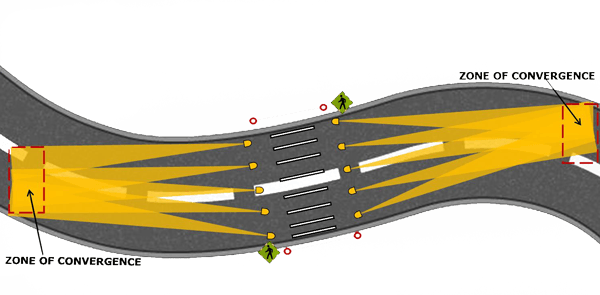

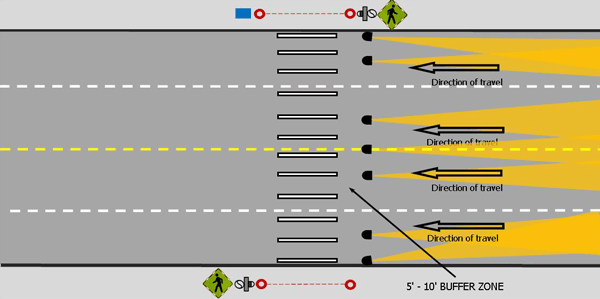

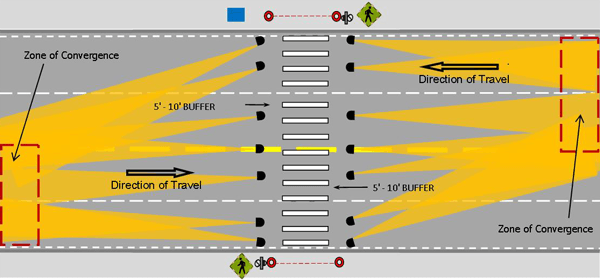

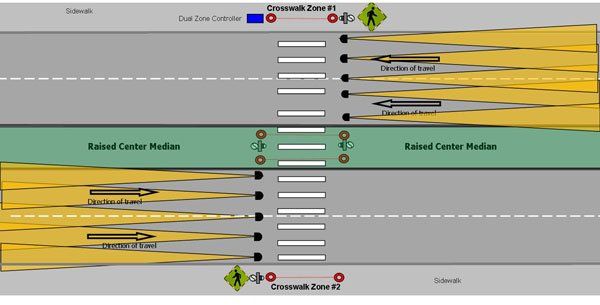

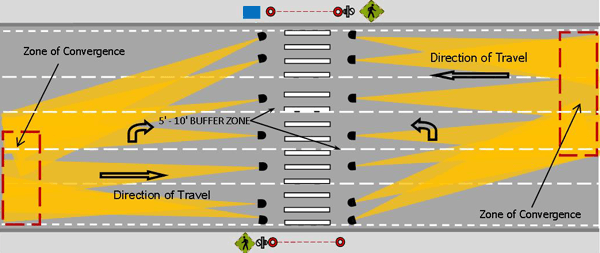

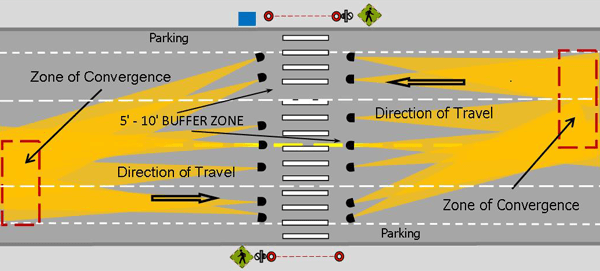

IRWL Roadway Layout Tips & Diagrams

When positioning the IRWL light fixtures, take great care to observe traffic flow patterns. The goal is to not place the IRWLs directly underneath wheel paths. Vehicle tires should straddle the IRWLs, not drive directly over them. General placement tips are below.

- Place IRWLs at the edges of the roadway to define the shoulders

- Next, place IRWLs on the centerline for a 2-Lane 2-Way crosswalk

- For crosswalks with a center turn lane, place IRWLs directly in the center, at the mid-point of the lane

- For all other remaining traffic lanes, place one IRWL fixture in the center, at the mid-point of each travel lane

- Aim each light fixture towards approaching motorists at eye level. The result is a unique position for each IRWL, as shown in the below diagrams

To learn more about our factory-recommended IRWL placements, refer to the LightGuard Systems Installation and User Manual and Zone of Convergence.

Common 2-Lane & 4-Lane Mid-Block Crosswalk Layouts

Have questions, or don’t see what you are looking for? Please contact us or call our office for assistance.

Product Spec Sheets

Studies & Reports

To date, there have been numerous studies determining the effectiveness of in-roadway warning lights (IRWLs) in a variety of settings and roadway safety applications.

Whether the study compares the effectiveness of overhead signals to IRWL, identifies ideal IRWL placement, or the efficacy of uni-directional IRWL systems, every IRWL study conducted leads to the same conclusion. The incidence of conflict between pedestrians and motorists decreases, and motorists yielding to pedestrians and stop time significantly increases.

Below are industry studies using LightGuard Systems' flashing in-roadway warning lights to illuminate pedestrian crosswalks, rail grade crossing vehicle stop lines, and to flash in sync with stop light signals at a controlled intersection.

Written Specifications

Bid specifications are critical to determining the exact nature of the crosswalk systems desired for a particular location. These are generic specifications written to provide easy-to-follow guidelines when developing bid package specifications.

The sections included are:

- Logic Control Device and Enclosure

- Solar Powered Logic Control Device and Enclosure

- In-Pavement Signal Heads

- LED Enhanced Pedestrian Crossing Symbol Signs

- Bollards

- Push-buttons

Product Warranties

LightGuard Systems (LGS) Product Warranty Policy for Products and Components

Subject to the Conditions and Exclusions noted below, LGS warrants to the end-user that each LGS product, when registered, installed, and operated under regular use and maintained according to the instructions furnished with the product, will be free from defects in materials and workmanship. LGS agrees that it will, at its option, either repair any such defect or replace the non-conforming product or part thereof with an equivalent replacement product or part at no charge to Buyer/end-user for LGS-branded or LGS-supplied parts for the periods set forth below:

5 Year Limited Warranty — Rectangular Rapid Flashing Beacons (RRFB), LED Signs, and base plates for a period of five years from date of installation. Warranty period will never start later than six months after the date of purchase from LGS.

3 Year Limited Warranty — In-Roadway Warning Lights (IRWL), Bollards, Controllers, and related cabling, for a period of three years from date of installation. Warranty period will never start later than six months after the date of purchase from LGS.

1 Year Limited Warranty — Third-party manufacturers’ non-value-added products such as batteries, enclosures, solar panels, push-buttons, static signs, etc., for a period of 1 year from date of installation. Warranty period will never start later than six months after the date of purchase from LGS. If a third-party manufacturers’ standard warranty period is greater, their warranty period will apply. In some cases, the Buyer/end-user may need to facilitate the warranty coverage directly with a third-party manufacturer rather than LGS.

For Limited Warranty coverage outside the USA, contact your local LGS representative, as coverage may vary.

Conditions & Exclusions of Warranties

All products must have been purchased from LGS or an authorized LGS Dealer. All LGS products are designed to function/operate as an integrated system. LGS does not warranty any of its products to function or provide any level of safety when directly integrated with other non-LGS products/brands.

This Limited Warranty does not cover any product that has been subjected to damage/abuse, misuse, alteration, neglect, unauthorized repair or installation, connection to an improper power source, operation beyond its manufactured specifications and limits, improper site preparation, maintenance not in accordance with manufacturer instructions, or operation with components not supplied or approved in writing by LGS, including, but not limited to, buttons, switches, system wiring, and cabling. Refer to the LGS manufacturer installation instructions.

This Limited Warranty is void if the product has been subjected to adverse conditions, or otherwise operated outside its specified environment; or if the FIELD RELATED TOTAL PREVENTATIVE MAINTENANCE (Section 8.3) of the LGS Installation Manual has been neglected.

This Limited Warranty does not cover the finish or non-functional appearance of any product. Buyer, if different than end user, shall be solely liable to the end-user for the condition of the products as installed. Buyer is also required to provide the end-user with all documentation related to this Limited Warranty as well as these Terms and Conditions.

*To properly register the 3 Year Limited Warranty on IRWL, LGS or an authorized Dealer must receive at the time of installation registration photographs clearly showing close-up details of each IRWL and their respective placement(s) from each other, a panoramic photo spanning the width of the entire IRWL installation from one end of the crosswalk to the other from both sides of the crosswalk, a photo of the approaching drivers’ viewpoint from both sides of the crosswalk, and photos of all other installed components and products.

LightGuard Systems is a registered trademark™ of LightGuard Systems, Inc. Smart Crosswalk is a trademark™ name of LightGuard Systems, Inc. ©2021 LightGuard Systems, Inc. All rights reserved.

Do You Want a Free Pricing Quote? Call LightGuard Systems at 707-542-4547!