Product Components – Features, Applications, Warranty, & Specs

At LightGuard Systems, we're deeply committed to ensuring pedestrian and motorist safety through our innovative product components. Our range of safety systems are meticulously designed, integrating cutting-edge technology, high-quality materials, and rigorous testing to provide effective solutions for traffic safety challenges. From traffic signal systems to pedestrian crossing products, we're at the forefront of developing equipment that keeps people safe on the roads, providing peace of mind for pedestrians, drivers, and city planners alike. Dive into the world of our robust safety systems and discover how we're shaping a safer future for everyone.

Want to learn more about the components that make up our pedestrian & motorist safety systems? Read more information on major components below, including features and benefits, applications, warranty & maintenance, and specifications.

Push Button Devices

LightGuard Systems offers a full range of manual and touchless pedestrian activation solutions to meet the evolving safety, accessibility, and public health needs of communities. Whether enhancing ADA compliance, improving crosswalk visibility, or helping to prevent the spread of contact viruses, our push buttons are designed to integrate seamlessly with our Smart Crosswalk™ systems, including in-roadway warning lights (IRWLs) and LED-enhanced signage.

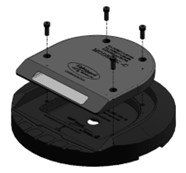

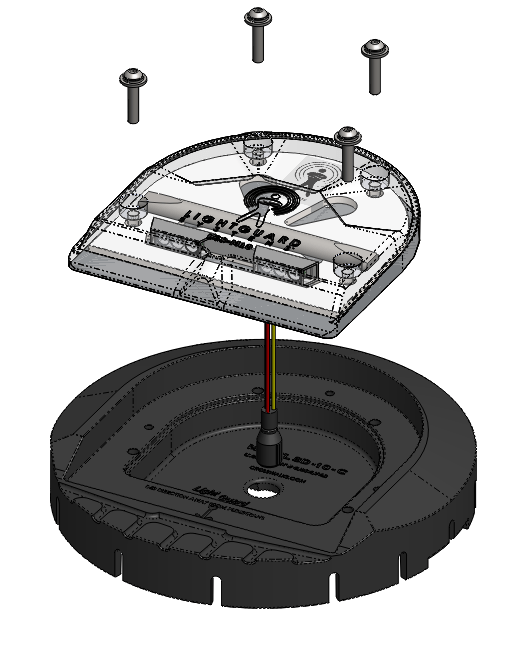

Smart Crosswalk™ Push Button Assembly (LGS-PBA)

Part Number: LGS-PBA

A durable, vandal-resistant push button assembly with four high-visibility amber LEDs that flash upon activation. Available with left or right-facing pedestrian figures.

Features & Benefits:

- ADA compliant

- Four synchronized flashing LEDs

- Easy installation and electrical connections

- 12 VDC operation (down to 9 VDC)

- Mounts to existing poles

- Sold in pairs (for both ends of crosswalk)

- Multiple placard options available

Specs:

- Operating Voltage: 9–15 VDC (only when flashing)

- Power: 1 watt

- Button: 2” silver mushroom vandal-resistant

- Color: Green anodized aluminum housing

- Operating Temp: -20°C to 80°C

Smart Crosswalk™ Push Button w/ Braille (LGS-PBA-BRAILLE)

Part Number: LGS-PBA-BRAILLE

Features the same functionality as the standard push button, but with an ADA-compliant Braille placard to support visually impaired pedestrians.

Features & Benefits:

- MUTCD R62E compliant

- Braille placard matches printed message

- Tamper-resistant hardware

- AC to DC converter included

- Sold in pairs

- Compatible with automatic detection bollards

Specs:

- Power: 1 watt

- Operating Voltage: 9–15 VDC (only when flashing)

- Operating Temp: -20°C to 80°C

- LED: Amber

- Button: 2” vandal-resistant mushroom

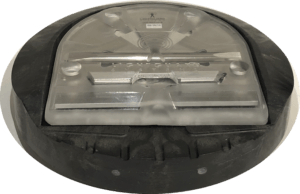

Smart Crosswalk™ Push Button (No LEDs) (LGS-PBA-R10-25 MUTCD)

Part Number: LGS-PBA-R10-25

This streamlined option omits LEDs and includes a MUTCD-compliant R10-25 placard, which comes in two sizes: 5”x7” and 9”x12”. Ideal for locations where flashing feedback is not required on the button itself.

Features & Benefits:

- ADA compliant

- MUTCD R10-25 compliant placard (5"x7" and 9"x12")

- Simple electrical connections

- 12 VDC operation

- Sold in pairs

- Easily mounts to existing poles

Specs:

- Operating Voltage: 9 VDC

- Button: 2” silver mushroom vandal-resistant

- Color: Green (around button)

- Operating Temp: -20°C to 80°C

Accessible Pedestrian Signal – Guardian (PBA-LGS-Guardian)

A full-featured APS push button system designed to aid pedestrians—particularly those who are visually or hearing impaired—at signalized intersections. The Guardian provides audible, tactile, and visual feedback, including vibro-tactile cues, speech messages, and visual LED signals.

Features & Benefits:

- Audible locator tone and speech walk messages

- Tactile vibrations during walk phase

- Visual LED confirmation of button activation

- Extended press for intersection-specific messages

- Ambient Gain Control (AGC) adjusts output to surrounding noise

- Beaconing, Group Walk, and custom configurations

- USB interface and easy field programming

- Meets MUTCD 4E and NEMA TS2 standards

- Night mode volume controls

Specs:

- Size: 5 x 13.75 x 1.75”

- Insert Size: 5 x 9”

- Max Volume: 100 dB @ 1m

- LED Output: 3000 mcd, 160° view angle

- Operating Temp: -40°C to +85°C

- Power: 1/3 watt (resting); 8.4W max

- Adjustable volume and vibro-tactile feedback

- Pedestrian data logging and system reporting

- Sign Sizes Available: 5x7.75”, 5x9”, 9x12”, 9x15”

- 3-Year Warranty

Installation:

Ships ready-to-install with a 4-wire interface connecting directly to the Signal Power Interface (SPI) in the pedestrian head. Angle-adjust brackets available for accessibility.

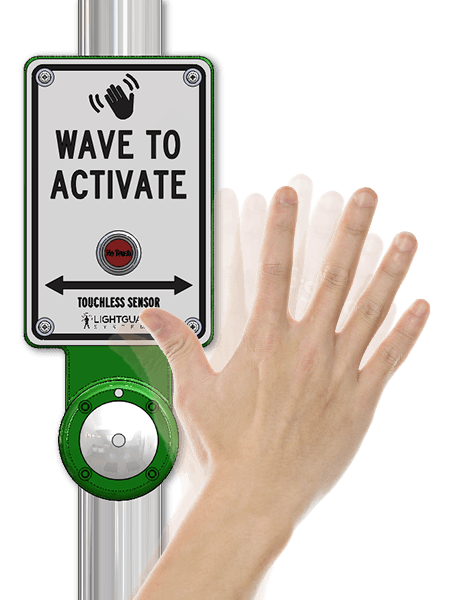

SmartSense™ Touchless Push Button Sign Upgrade Kit

Part Number: LGS-PBA-SMART

Designed in response to COVID-19, the SmartSense™ touchless activation kit helps reduce the spread of viruses by eliminating physical contact with public crosswalk buttons. Using short-range infrared (IR) proximity technology**, SmartSense™ activates a pedestrian call with the wave of a hand, helping to reduce cross-contamination at one of the most frequently touched public surfaces.

Key Benefits & Features:

No-touch activation—reduces virus transmission risk

Infrared sensor detects hand movement before contact is made

Compatible with all LightGuard Systems IRWLs, RRFBs, and LED sign systems

Can also be retrofitted to work with most existing push-button assemblies

Ideal for public health initiatives, especially in high-traffic or urban areas

Helps municipalities, cities, and agencies support hygienic public infrastructure

The SmartSense™ mechanism mounts within a compatible push-button station or directly to a pole adjacent to an existing push button. When a pedestrian approaches and gestures toward the device, the proximity sensor detects motion and triggers the crosswalk controller—all without physical contact. The sensor is designed to supplement the LGS-PBA manual button, ensuring redundancy and accessibility while providing a safer, touch-free alternative.

Technical Overview:

- Sensor Type: Short-range infrared proximity

- Operation: Activates crosswalk signal via relay

- Installation: Retrofits into most existing PBA stations or mounts near pole

Compatibility:

- LightGuard IRWL, RRFB, LED-enhanced systems

- Most third-party PBA controllers

- Use Case: Ideal for high-use areas, pandemic response, and accessibility upgrades

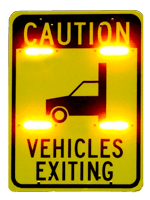

Custom Flashing LED Warning Signs

LightGuard Systems’ custom flashing warning signs provide highly visible, LED-enhanced messaging to alert both pedestrians and motorists in a wide range of environments. From crosswalks and parking facilities to golf courses and trails, these signs offer flexible safety solutions tailored to fit the specific needs of each location. Each sign is custom-designed and available in a variety of standard and oversized formats, with embedded LED lights that deliver immediate attention to critical safety messages. Powered by either Solar or AC, LightGuard’s flashing signs are built to perform reliably in diverse settings, offering agencies and property owners a durable, eye-catching way to improve awareness and reduce risk.

Ready for a Free Pricing Quote on Any of Our Pedestrian Safety Systems? Call LightGuard Systems at 707-542-4547.